I definitely agree this system is complicated, with lots of

factors at play.

In looking at the data we have been collecting this year a few

additional thoughts:

1)

It appears flow rate (detention time) in the pipeline is a very

large factor. I have attached some graphs comparing this summer to last year.

These data show that we are losing chloramine at almost the same rate,

not only between this year and last year, but also between RC and CC lines. I

am working on compiling more of this data that we have collected and plan to

plot on the same graph so we can see the trends better. Now that we are (or

planning to be) pumping at higher flow rates, we will see if this trend holds

true.

2)

From some other work we did, we can show that nitrifiers are

present - We see much less chloramine loss in pipeline samples that are filter

sterilized.

3)

We got TOC samples back from our last sample event (8/19/2015)

and TOC is much greater this year in Cedar Creek. This will lead likely to

higher chloramine demands. I think this may also result in lower conversion

efficiency. It has been difficult to gauge this year because of the low flows,

but now that we are pumping at higher rates we will be able to compare this.

TOC results are below:

a.

Cedar Creek – 5.8 (in 2014) vs. 7.5 (2015)

b.

Richland Chambers – 4.5 – 5.0 (in 2014) vs. 4.8

c.

Benbrook – 4.7 (in 2014) vs. 4.9

4)

From what I have seen, DO varies diurnally at the intakes due to

algae, even though we aren’t pulling right off of the surface of the lakes –

this will impact DO levels in the pipelines. As mentioned, biological activity

consumes DO. For example during nitrification:

a.

AOB convert ammonia to nitrite – this process consumes 3.16 mg/L

DO per mg of ammonia as N

b.

NOB convert nitrite to nitrate – this process consumes 1.1 mg/L

DO per mg of nitrite as N

c.

So when we have complete nitrification in the pipeline (all

ammonia taken to nitrate) for each mg/L of N, we will lose 4.24 mg/L of DO.

d.

We are currently dosing about 1 mg/L of ammonia to form

chloramines; not all of this will be converted to ammonia when the chloramines

decompose, but a significant fraction may. I am working on estimating how much

ammonia we can expect to be available for nitrification.

e.

It would be interesting to track DO based on travel time (like

we did for chloramine loss) to see if we see the DO loss at the same

approximate travel time in the pipe and if we see a difference in DO loss in

years when chloramines weren’t fed to when they were. I imagine as we travel

down the pipeline, the biological community changes based on what “food” is

present. However, it would be interesting to see if the shift in

community will result in more or less DO being consumed when we compare feeding

chloramines to not feeding chloramines or comparing low flow rates (this year)

to high flow rates (last year) when we were feeding chloramines.

I plan to continue hashing this stuff out…….

Thanks,

Greg

From:

David Marshall [mailto:David.Marshall@trwd.com]

Sent: Monday, August 31, 2015 10:03 AM

To: Shelly Hattan; Mark Ernst; Donna Stephens; Jason Gehrig; Rachel

Ickert; Greg Pope; Robert Cullwell; Darryl Corbin; Troy Laman; Darrel Andrews;

Chris Zachry; Alice Tu; Jim Gallovich

Subject: RE: Low Oxygen in the pipeline

A couple of other things to consider:

1.

BOD and COD are highest in the water column during the

summer. This year I would expect it to be greater than normal thanks to

the nutrient slug from the floods.

2.

The diurnal swings of DO in the reservoir may influence what we

are pumping. Pumped water is slug flow, so if the time of sampling could

be compared to the time it began to be pumped, the change may provide some

insight. For example, we start the sampling at the lake stations early in

the day. The wetwell is full of oxygen rich water since the lake has

started photosynthesis, adding oxygen. As the samplers move down

the line, they encounter water that was pumped at night when the lake was fully

in respiration.

The community in the pipeline and the chemistry is complex.

David H. Marshall, P.E.

Director of Engineering and Operations Support

Tarrant Regional Water District

800 East Northside Drive

Fort Worth, Texas 76102

Office: 817.720.4250

Cell: 817.475.0061

twitter @trwd_news

From:

Shelly Hattan

Sent: Monday, August 31, 2015 8:27 AM

To: Mark Ernst; Donna Stephens; Jason Gehrig; David Marshall; Rachel

Ickert; z Greg Pope; z Robert Cullwell; Darryl Corbin <DCorbin@carollo.com> (DCorbin@carollo.com); Troy Laman (TLaman@carollo.com); Darrel Andrews; Chris

Zachry; Alice Tu; z Jim Gallovich

Subject: RE: Low Oxygen in the pipeline

My hypothesis is this:

·

Cooler temperatures = low biofilm activity.

·

Flow rate = differing biofilm thicknesses – the faster the

velocity, the flatter the biofilm gets (viscoelasticity of biofilm)

·

DO = lowers with higher biofilm activity. We see a spike up in

DO when we boost pumping (read: Ennis (25.5) and Waxahachie (43)) since the

water has to recycle through the tanks. It’d be interesting to see what the DO

is before entering the tanks and then after. Not sure if sampling was done on

suction side or discharge.

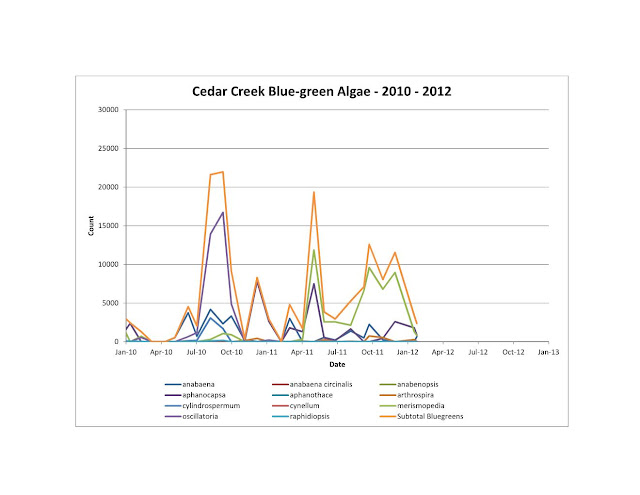

I believe the algae in the water enters the pipe, respires and

introduces CO2 in the water. With the algae data we have, it looks like we see

a change when the blue-greens and the flagella (?) are highly active. I never

did go back and try to correlate the algae data with your LSI results. Could

prove to be interesting. The CO2 then gets used by bacteria to start growing –

and I believe since we are nitrifying in between Ennis and Waxahachie, we have

an Ammonia Oxidizing Bacteria strain in the pipe. The AOB then starts

using the oxygen, which brings down DO. The increase in CO2 also increase

bicarbonate when combined with water (HCO3-). Bicarb then helps contribute to

the carbonation occurring in the concrete core of the pipe – hence the loss of

CaOH from our concrete (i.e. a direct result of low LSI’s). I plan on using the

petrographic sampling program results to compare the material loss with the DO

data to see if there’s any relationship I can tease out of it.

I believe the use of Chloramines helps in a number of ways:

Stabilizes biofilm growth. Compare the 2010 data with the 2012

data. DO loss should not be as dramatic. I think if we could maintain a

residual higher than 1 (possibly around 2 to keep nitrification at bay), we’d

see DO stay far more consistent. I found in my thesis work that the friction

factor has an inverse relationship with DO, which I interpret as what I’m

hypothesizing.

That’s my 2 cents worth. Also note, that RC looks like it

behaves differently. I believe we have a different type of bacterial colony

established there. I’d like to prove that out by sampling some blow offs – I

believe we could close the butterfly valves and be able to scrape samples from

inside the manway.

I’d love to hear something from our consultants to verify some

of my thoughts.

From:

Mark Ernst

Sent: Monday, August 31, 2015 7:57 AM

To: Shelly Hattan; Donna Stephens; Jason Gehrig; David Marshall; Rachel

Ickert; z Greg Pope; z Robert Cullwell; Darryl Corbin <DCorbin@carollo.com> (DCorbin@carollo.com); Troy Laman (TLaman@carollo.com); Darrel Andrews; Chris

Zachry; Alice Tu; z Jim Gallovich

Subject: RE: Low Oxygen in the pipeline

The graph below includes the last of July and the month of

Aug in 2010 where the dissolved oxygen really tanked. If you look through all

of these graphs and then cross your eyes and look through them again it seems

like the dissolved oxygen in the line is a result of the temperature of water,

flow rate in the pipeline and standing crop of biofilm in the pipeline. I

know the oxygen is negatively related to temperature, think it is positively

related to flow and an guessing it is negatively related to biofilm. Be real

cool to quantify this!

From:

Shelly Hattan

Sent: Friday, August 28, 2015 3:37 PM

To: Donna Stephens; Jason Gehrig; Mark Ernst; David Marshall; Rachel

Ickert; z Greg Pope; z Robert Cullwell; Darryl Corbin <DCorbin@carollo.com> (DCorbin@carollo.com); Troy Laman (TLaman@carollo.com); Darrel Andrews; Chris

Zachry; Alice Tu; z Jim Gallovich

Subject: RE: Low Oxygen in the pipeline

The LSI study had some really good data on this:

2010

2011

2012

2013

From:

Donna Stephens

Sent: Friday, August 28, 2015 3:06 PM

To: Jason Gehrig; Mark Ernst; David Marshall; Rachel Ickert; z Greg

Pope; z Robert Cullwell; Darryl Corbin <DCorbin@carollo.com>

(DCorbin@carollo.com); Troy Laman (TLaman@carollo.com); Darrel Andrews; Chris

Zachry; Alice Tu; z Jim Gallovich; Shelly Hattan

Subject: RE: Low Oxygen in the pipeline

Thanks Mark,

Do we know the depth (in the reservoirs) that the water becomes

hypoxic, anoxic, anaerobic?

The latest Zebra Mussel video post from TPWD…

Donna Stephens | Infrastructure Engineering Services

Tarrant Regional Water District | Direct:

817-720-4251

From:

Jason Gehrig

Sent: Friday, August 28, 2015 1:32 PM

To: Mark Ernst; David Marshall; Rachel Ickert; z Greg Pope; z Robert

Cullwell; Darryl Corbin <DCorbin@carollo.com>

(DCorbin@carollo.com);

Troy Laman (TLaman@carollo.com);

Darrel Andrews; Chris Zachry; Donna Stephens; Alice Tu; z Jim Gallovich; Shelly

Hattan

Subject: RE: Low Oxygen in the pipeline

This looks interesting Mark. If ZM’s won’t attach in <2

DO environments, perhaps we could develop a zebra mussel/biofilm control

approach where min 0.3 to 0.5 chloramine residuals throughout the entire

system-wide wouldn’t be required; but rather only in areas of the pipeline

where DO’s are expected to exceed 2 mg/L. This would probably meet our biofilm

control needs at the same time since we already chloramine feed there, at least

in the longer stretches of higher head pumping (i.e. lake ps’s to Wax or

so). Adding chloramine feed at BB would still be needed but boosting

requirements could be re-analyzed.

A good review of our seasonal DO data in our pipeline might shed

additional light.

Thanks,

Jason

Also good info on hypoxic vs anoxic vs anaerobic as well

From:

Mark Ernst

Sent: Friday, August 28, 2015 11:45 AM

To: Jason Gehrig; David Marshall; Rachel Ickert; z Greg Pope; z Robert

Cullwell; Darryl Corbin <DCorbin@carollo.com>

(DCorbin@carollo.com);

Troy Laman (TLaman@carollo.com);

Darrel Andrews; Chris Zachry; Donna Stephens

Subject: Low Oxygen in the pipeline

Interesting paper on the tolerance of zebra mussels to low

dissolved oxygen levels. The paper talks about “hypoxic levels” of

dissolved oxygen which are defined as less than 2 mg/L (Anoxic levels are

less than 0.5 mg/L). The results show that at 25 C (77 F) mean

survival of zebra mussel adults was 2 to 3 days under hypoxic conditions.

Downstream from Wax Pump Station we get these conditions for about 2 months.

Yesterday at Midlothian Hill the dissolved oxygen in the CC

line was .26 mg/L and in the RC line was .22 mg/L at 29 C (84 F).

This was maintained to the KBR structures. I think we have an environment that

is not suitable for zebra mussel infestation.

Catch-22

The loss of oxygen in the pipeline downstream of Wax may

be accelerated by biofilm growth and bulk bacterial growth. If we

boost chlorine in the Wax area to reduce biofilm in the line downstream to KBR

as a measure to reduce pipeline friction, then dissolved oxygen may remain high

enough for zebra mussels.

Some suggest we have a similar dilemma with our bottom

aeration of the intake areas at Lake Benbrook and Lake Bridgeport, where we

might be creating a habitat for zebras where there was once not one. I

don’t think so, our data from this summer at Bridgeport shows that even with

our new diffuser configuration we are still going anoxic near the bottom,

however we are not going anerobic. Anerobic is where all the dissolved

oxygen is gone and bacteria start to scavenge oxygen from molecules like SO4

and make H2S. So, no new zebra mussel habitat and a reduced

amount of anerobic bad boys.

Welcome your thoughts on this.

Mark

R. Ernst

TRWD

817-999-9832

cell

817-237-8585

office